008615129504491

| Yawan amfani da maki sune | Gr5(Ti-6Al-4V), Gr23(Ti-6Al-4V ELI), Ti-6Al-7Nb |

| Daidaitawa | ASTM F136, ISO 5832-3, ASTM F1295/ISO 5832-11 |

| Diamita | 3-100 mm |

| Hakuri | h7, h8, h9 |

| Surface | goge |

| Madaidaici | A cikin 1.5 ‰ |

| Halaye | Za mu iya yin manyan ayyuka na musamman na samfuran ku |

| Abubuwan sinadaran | ||||||||

| Daraja | Ti | Al | V | Fe, max | C, max | N, max | H, max | O, max |

| Ti-6Al-4V ELI | Bal | 5.5 ~ 6.5 | 3.5 ~ 4.5 | 0.25 | 0.08 | 0.05 | 0.012 | 0.13 |

| Darasi na 5 (Ti-6Al-4V) | Bal | 5.5 ~ 6.75 | 3.5 ~ 4.5 | 0.3 | 0.08 | 0.05 | 0.015 | 0.2 |

| Ti-6Al-7Nb | Bal | 5.5 ~ 6.5 | Nb: 6.5 ~ 7.5 | 0.25 | 0.08 | 0.05 | 0.009 | 0.2 |

| Kayan aikin injiniya | |||||

| Daraja | Sharadi | Ƙarfin Tensile (Rm/Mpa) ≥ | Ƙarfin Haɓaka (Rp0.2/Mpa) ≥ | Tsawaitawa (A%) ≥ | Rage Wuri (Z%) ≥ |

| Ti-6Al-4V ELI | M | 860 | 795 | 10 | 25 |

| Darasi na 5 (Ti-6Al-4V) | M | 860 | 780 | 10 | / |

| Ti-6Al-7Nb | M | 900 | 800 | 10 | 25 |

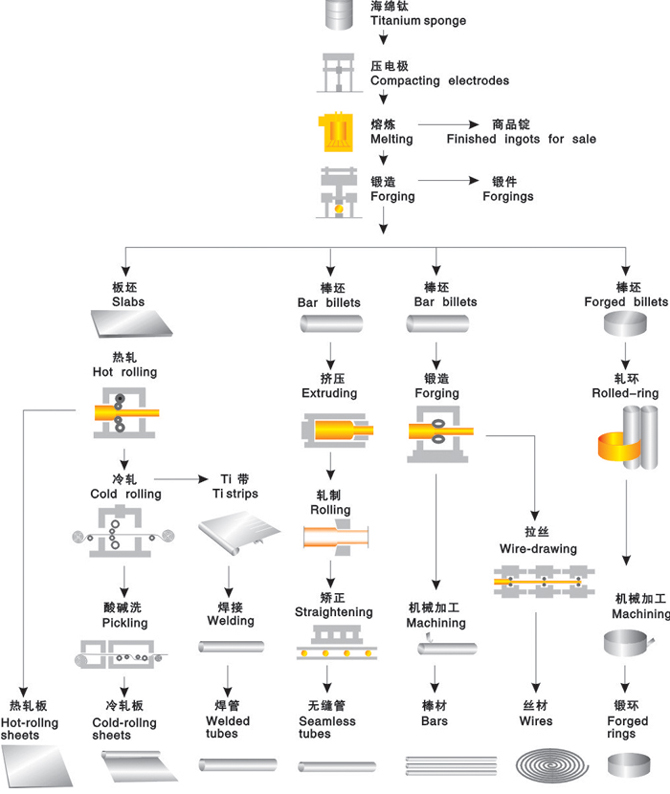

XINNUO ya shigo da Jamusanci ALD Vacuum Oven don narkar da titanium ingot da kansa tun 2016, ya narke sau 3 don tabbatar da abubuwan haɗin sinadarai, da alama lambar zafi daga titanium ingot zuwa kowane tsarin samarwa daga baya, ana buga shi akan sandunan gogewa na ƙarshe don bin diddigin gaba.

Tare da kowane nau'i na kaya, muna gwada ƙarfin ƙarfi ta Tester ɗinmu na Tension kuma muna ɗaukar samfurin zuwa dakin gwaje-gwaje na ɓangare na uku, samar da Takaddar Gwajin Mill ga abokan ciniki.

100% ultrasonic flaw gano, yawan zafin jiki da kuma samar da tsari ne gano, da kuma XINNUO daukan kaya 'quality a matsayin na farko da muhimmanci a lokacin da dukan samar da tsari, ba zai bari m kayayyakin tsĩrar da daga factory, alhakin kowane tsari na kaya kawota.